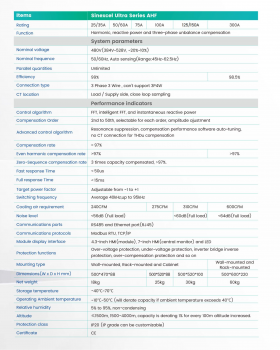

Sinexcel Ultra SiC (silicon carbide) range of advanced active harmonic filters are currently available from 220V up to 480V (690V shortly). Designed with ‘oilfield electrification’ in mind, Ultra SiC AHF provides unique features, high THDi performance, “sensorless control” option to minimise background THDu, combined with small physical sizes and low cost.

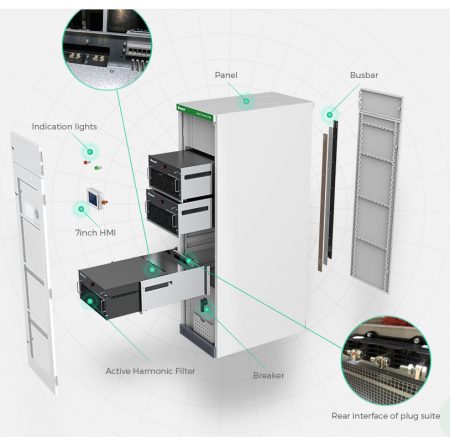

Available in IP20, modules with three mounting options (i.e. wall, rack and ‘bookcase’) from 15A up to 300A (can be paralleled up for higher ratings) and in enclosure options up to IP54 and 1200A per enclosure.

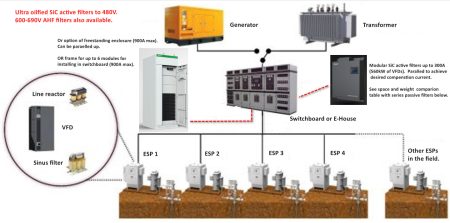

The IP20 modules are ideal for installation in oilfield E-Houses, switchboards, panels and VFD enclosures, or any application where lack of space or cost of installation is an issue (e.g. landrigs being converted to utility supplies, offshore platforms and supply vessels, FPSOs, or as per the example below, jackup drilling rig VFDs rooms as seen below).

Ultra SiC active filters are ideal, when mounted in ‘bookcase design’, for VFD enclosures, switchboards and panels (see below). For example, a single 150A can provide <5% THDi mitigation for up to 280kW VFD load. A 300A filter can mitigate ~ 450kW of VFD loads. For higher compensation current ratings, modules can be paralleled..

Enclosure options available include IP20 for panel mounting, enclosures, IP23 up to IP54 and 1200A maximum per enclosure. Customer enclosures also available. The compensation current capacity can be expanded if additional VFDs, for example are added to the field, thus ensuring a future-proof solution.

Note : Ultra static VAR generator (SVG) modules of same physical design can be mixed with Ultra SiC to also provide electronic displacement power factor correction.

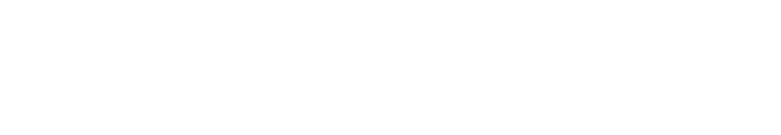

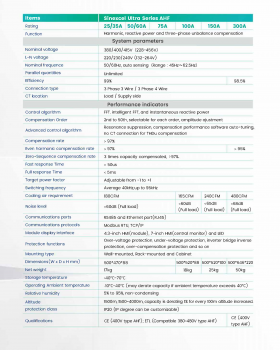

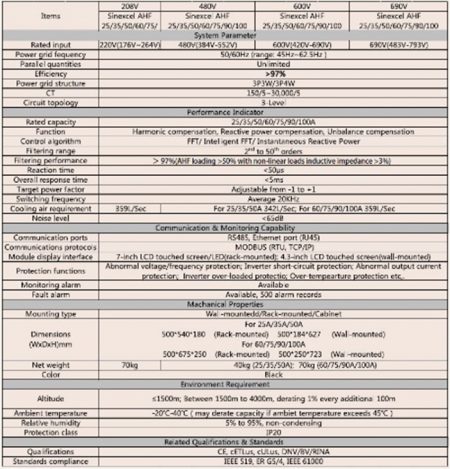

Specifications:

Comparison of Series Passive Filters and Ultra SiC

An example below illustrates a comparison of the required physical space required in an E-house or switchboard for series passive filters, historically the mitigation of choice for ESP VFD ‘at the wellhead’ mitigation and Ultra SiC active filters.

Three examples are provided. The dimensions and weights of the passive filters were taken from a leading European manufacturer’s datasheet. In each case the Ultra SiC filter was mounted as a “bookcase” installation where multiple filters are installed side by side, vertically to minimise space.

Note – series passive filters must be sized to the VFD kW where Ultra SiC (and other harmonic active filters) should be dimensioned based on the maximum harmonic current.

NA AHF active filters

Ultra SiC active filters currently are only available in voltages to 480V. For voltages from 208V to 600V/690V, (800V for renewable applications), the NA AHF active filter is available in rack or wall mounting.

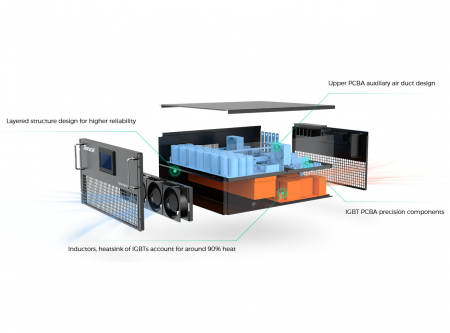

These three level IGBT active filters have similar features as Ultra SiC AHF but are of different construction and packaging.

Specifications:

Ultra SiC and AHF additional features

– Unique intelligent Fourier technology

Resonance is a serious electrical problem. When a local power system resonates, it will generate harmonic voltages and harmonic currents to dangerously elevated levels across all equipment on the local network.

Since 2017, Sinexcel has utilised specifically designed resonance suppression into their active filter technology via their uniquely Intelligent Fast Fourier Technology and lead the field in resonance suppression technology. This technology ensures stable operation of the system thus avoiding the effects of resonance.

In 2022, after several more years of persistent research and development, Sinexcel’s R&D team launched Resonance Algorithm 2.0. Based on higher levels of resonance suppression, they further improved resonance compensation with a THDi of 5% and output perfect sine waves bringing enhanced power quality for the user.

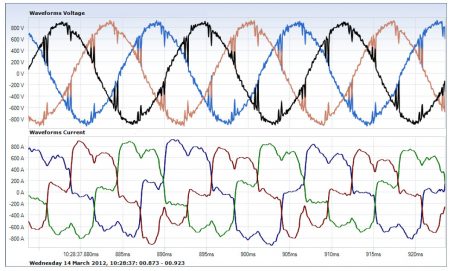

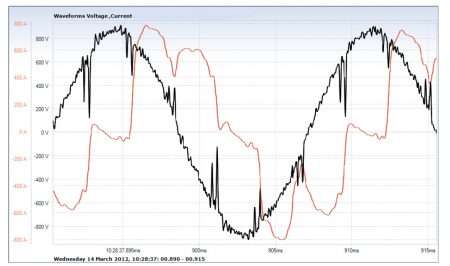

Voltage control (aka sensorless control)

The importance of attenuation of background THDu cannot be understated. Large onshore installations, offshore production platforms, FPSOs and drilling rigs are examples which have large, multiple VFDs and/or DC drives. This can result in harmonic voltage (THDu) levels which far exceed the design of the installations and the harmonic recommendations which govern their use. This excessive THDu can often reach levels which can adversely affect both operations and safety on MV and via LV levels.

Excessive THDu can interfere with monitoring and protection systems and all other equipment including electric motors, especially fixed speed explosion motors where under certain circumstances, these motors may present ignition risk and be potentially dangerous.

Ultra and NA AHF active filters both have the following control options :

- Open loop (load sensing with the CTs on the side)

- Closed loop (source sensing with the CTs upstream of the active filter connection)

- Voltage control (where CTs are not required since special control is activated)

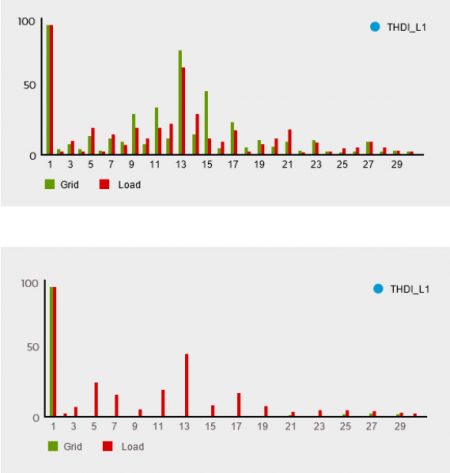

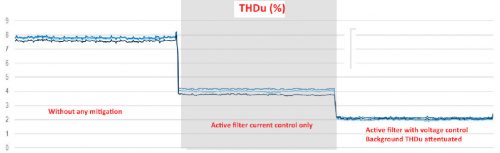

Voltage control directly targets the voltage waveform instead of injecting a compensation current solely based on the current measurement and enables sensorless operation without current transformers, often with better results as illustrated below.

‘Voltage control’ is a fundamental requirement for the mitigation and attenuation of background voltage distortion (THDu) (i.e. the local reduction of voltage harmonic levels from medium voltage networks with excessive THDu) impressed on LV supplies and equipment.

Brochures with specifications

Hybrid module application

Ultra SiC modules can be installed in dedicated enclosures to 1200A or a mix of Ultra SiC and Ultra SVG Power Factor Correction, making it a more economical power quality solution as AHF compensates harmonics, and SVG compensates reactive power at same time.

For information on Ultra SiC SVG (electronic PFC)

RiteSineLab harmonic simulations

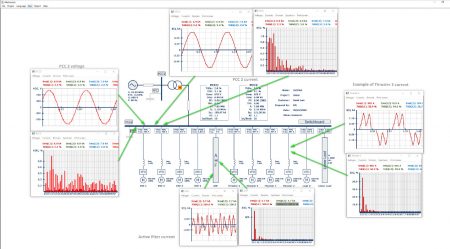

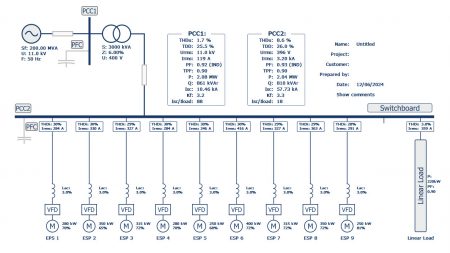

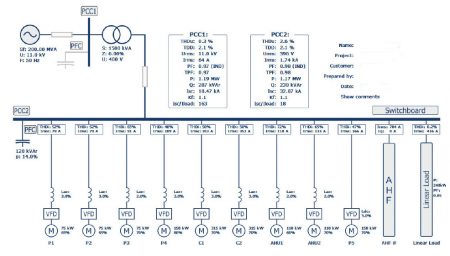

RiteSineLab harmonic simulation software simulates 6 pulse VFDs, DC drives, programmable current source devices, PFC and linear loads. For mitigation, both series passive filters and active filters can be modelled. Up to 30 nodes can be accommodated.

Considered in the calculations are :

- Transformers (including those for each node, if applicable)

- Generators (up to 8 off in parallel)

- Transformers per node

- Cables

- Drive reactors (AC and DC bus)

- Linear loads

- Power factor correction

- Background harmonic voltage distortion

- Voltage asymmetry (imbalance)

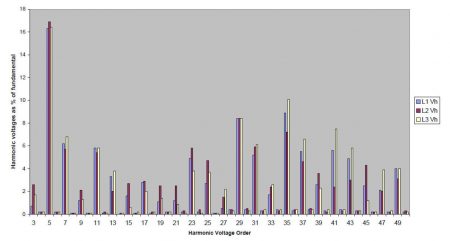

After a simulation has been run, a report is available based on IEEE‐519‐1992, IEEE‐519‐2014, IEEE-519-2022 and other harmonic recommendations and rules, the latter mainly for marine and offshore use. In addition, at the source; transformer or generator, switchboard, PFC, discrete drive and linear load nodes a full set of voltage and current waveforms and harmonic spectra are available. The harmonic spectra, although set by default 50th order, can also present harmonics to the 100th.

Typical Oilfield Applications

– ESP and sucker rod pump VFDs

Historically, ESPs and sucker rod pumps were supplied from generators, where power quality was not necessarily a major consideration. However, with the trend to oilfield electrification accelerating to connection onto utility supplies, maintaining acceptable power quality has become extremely important. In addition, the efficiency, performance and physical size and cost of is crucially important when harmonic mitigation is to be installed in switchboards and E-Houses.

Ultra SiC is an advanced, high performance active filter range which offers economical ‘global mitigation’ for multiple ESP VFD or sucker rod pump applications as illustrated below. It is more cost effective when installation, maintenance, space, weight are considered yet ensuring high THDi performance. Can also be installed in ESP VFD enclosures.

Refer to comparison table in Ultra SiC section for examples of comparison of physical size between series passive filter and Ultra SiC active filter mitigation

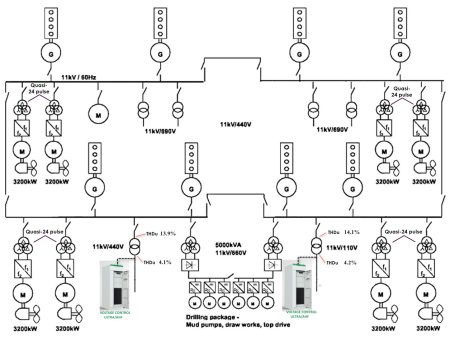

– Platforms, drilling rigs and FPSOs

There are always concerns on offshore drilling rigs, oil production platforms and FPSOs regarding the lack of physical space and the weight of variable speed drives (AC and DC) and their associated equipment, including harmonic mitigation). On platforms and FPSOs this factor can limit the number of ESP VFDs (and their harmonic mitigation) installed and therefore, the production throughput, especially if series passive filters and/or multi-pulse VFD are employed.

In addition to normal active harmonic current control via CTs, Ultra SiC and NA AHF can both also offer sensorless voltage control to attenuate background THDu to protect equipment seen downstream and reduce the THDu impressed on the LV supplies and connected equipment.

– Voltage control (aka sensorless control)

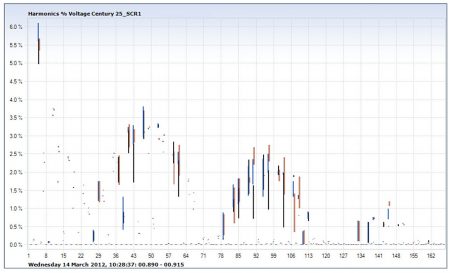

An example of the use of Ultra SiC voltage control on semi-submersible drilling rig is depicted below.

Comments – The salient non-linear loads on the DP semi-submersible rig were eight quasi-24 pulse thruster VFDs and a common DC bus VFD drilling package. During operations, the average THDu appearing on the LV supplies (440V and 110V), which also fed lighting and other transformers was captured at 13.9-14.1%. This excessive THDu (on an installation designed for <8%) resulted in continual damage and disruption to susceptible and sensitive LV equipment, most of which are only designed to withstand <5% THDu.

– Conversion of landrigs to utility supply

As part of oilfield electrification, many landrigs will be converted to local utility supplies. This requires compliance with utility rules, national and international standards on power quality (<5% THDu at LV) and displacement power factor (0.95 lagging).

Landrigs are renowned for their lack of space. Since many have SCR (DC drives), often without AC line reactors, this presents challenges as AC line reactors are usually a prerequisite for applying active filters to attenuate the high frequency notching voltage harmonics.. With Ultra SiC active filters, there may be various alternatives, depending on the system design and other factors.

Due to their small physical size and performance, Ultra SiC active filters (and Ultra SVG for PFC) are ideally suited to installation in and on Landrigs, in air-conditioned E-house or dedicated equipment containers including inside VFDs and/or switchboards.

Harmonic Solutions Oil & Gas has the knowledge and experience

When applied correctly, active filters are an important tool in the harmonic mitigation toolbox. However, no form of harmonic mitigation is perfect. The secret of success is recognising the pros and cons of all types of active and passive mitigation and being able to apply the most appropriate form of mitigation for any given application.

The staff at Harmonic Solutions Oil & Gas have been involved in applying active and series passive filters since 2003 to on demanding marine and offshore applications since 2007 with our site harmonics. PQ and site services.

Contact us with your application details and let us assist you.