Ultra SiC Static VAR Generators

Capacitor-based low voltage (LV) contactor and SCR switched power factor correction (PFC) systems have been employed for correcting displacement power factor for around the past 60 years. In that time, there has many improvements in capacitor and switching designs. When correctly designed, these PFC systems can be reliable and rugged. However, there are many capacitor-based systems installed which struggle technically with harmonics, leading displacement power factor, system response time, and temperature challenges. While most of the challenges can be overcome with the correct design, correct component selection and superior quality manufacture, there are alternate technologies now available.

Conventional capacitor systems are available with SCR (i.e.) thyristor switches instead of conventional contactors. This can make them a fast-acting solution, operating within 30 milliseconds, still not as fast as an SVG, but fast enough for most applications but failed to address both leading and lagging DPF.

Over the last 10 years, active (i.e. electronic) PFC systems or ‘static VAR generators’ (SVGs) have become available for LV applications and are now seriously challenging conventional power factor correction equipment. SVGs are simple in concept but do require significant expertise in electronic design due to an assortment of individual components. Their flexibility is excellent, and there is no doubt that as electronics become simpler and more reliable, these systems will eventually seriously challenge conventional PFC systems.

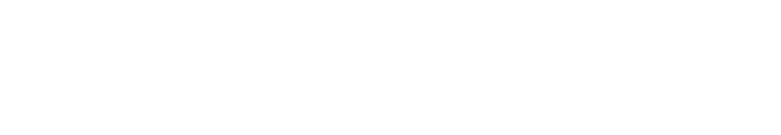

The basic principle of an SVG is illustrated above. The SVG operates by detecting the load current in real time via external CTs and thus determines the reactive components of the load. The data is analysed by the SVG control system which adjusts the triggering of the PWM of the IGBTs (or SiC) device firing such that the SVG inverter produces the exact reverse reactive current of the corresponding load current reactive content. The resultant current is injected into the grid to compensate for the reactive content of the load current. By controlling the SVG output voltage amplitude and phase angle, or directly controlling the AC current, the SVG can absorb leading VAR or generate lagging VAR according to the load reactive power or grid voltage level.

Ultra SiC SVGs

Ultra SiC SVGs are very similar to their SiC active filters counterparts.. Both are modular in construction and of identical physical sizes. Ultra SiC can combine both harmonic mitigation (AHF) and reactive power control (SVG) in one enclosure or modular system.

Ultra SiC SVGs are available currently up to 480V in various kVAr ratings which can be paralleled up to the desired rating.

Ultra SiC SVGs and active filters can be combined as modules or in enclosures, connected to PCC (i.e. point of common coupling) thus providing harmonic mitigation and reactive power control.

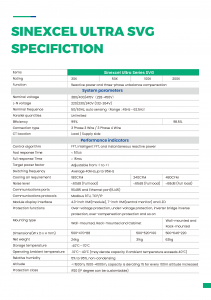

Specifications:

NA Static VAR Generators

Presently Ultra SiC SVGs (and active filters) are only available to 480V. Above that voltage level another SVG range available from 208V to 690V. For renewable applications the SVGs up t0 800V are also available.

All NA models are suitable for wall and rack mounting is suitable enclosures.

Specifications:

For generator applications

Static VAR generators SVGs) can be used to compensate for lagging and leading displacement powers factors. Their speed of response is significantly faster than contactor or SCR based traditional capacitor-based PFC systems.

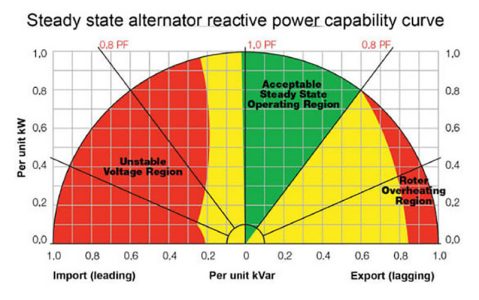

SVGs can be applied to utility-based power systems and generators. The typical generator capability curve is illustrated below. As can be observed, the generator’ unstable voltage region’ is clearly seen.

Examples of where SVG can be used:

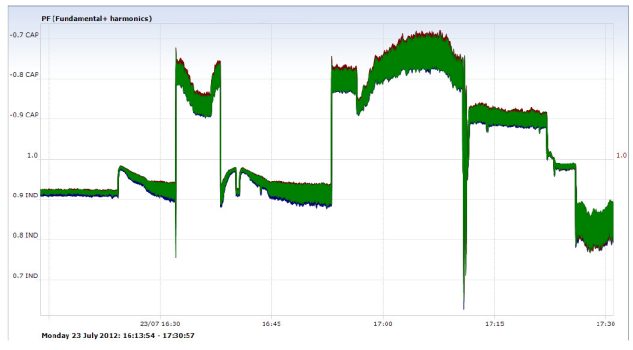

Example of ship (1 off 9 in class) with 3 x 2500kW AFE VFDs. At no, light or intermittent load, DPF was unstable, toggling between 0.82 lag – 0.73 lead. This resulted in blackouts due to generator AVR tripping. SVG would provide lagging VARs to compensate for leading DPF.

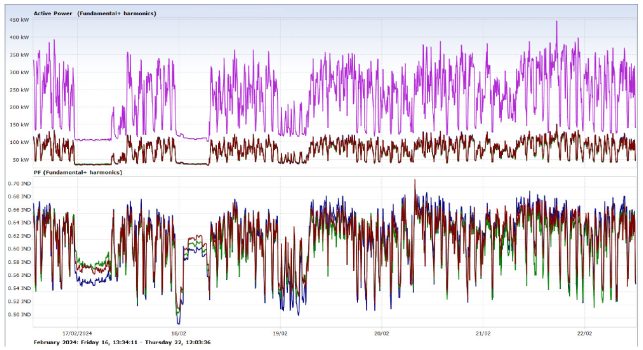

Generator based system with two manually controlled, passive harmonic filters/PFC. Leading DPF occurred when one or two filters not disconnected when system lightly loaded. SVG would provide lagging VARs to compensate for leading DPF.

Factory subject to wide range of lagging and dynamic DPF. Passive PFC too slow to react effectively. SVG would provide leading VARs timeously to compensate leading DPF.

SVG Brochures

Harmonic Solutions Oil And Gas has the knowledge and experience

Contact us with your application details and let us assist you.